Basic Motivation and Objective:

Metallurgists and ceramists have long recognized that most apparently homogeneous materials in fact possess several levels of structure between the atomic and the macroscopic. These substructures, generally termed microstructure, include dislocation networks, precipitate dispersions, grain arrays, phase distributions, and engineered substructures which contribute to the surface anisotropy of the grains.

As the part of our coursework in ME-574 we have tried to primarily look into the following issues:

1) Understanding the primary experimental variables and surface reaction paths controlling nucleation/ growth kinetics and microstructural evolution during vapor-phase deposition.

2) Developing an appreciation of the advantages/disadvantages of competing growth techniques.

3) Learning how to better design film growth processes.

As the part of my project I have specifically looked into how we can obtain various interesting polygonal structures with various orientations by inducing a surface anisotropy by controlling the temperature around the surface of a material whose surface tension is directly proportional to the temperature it is exposed to. Due to surface anisotropy, small particles of many crystals take shapes of polyhedrons, with flat facets and sharp edges and corners.

Given the surface tension as a function of crystal surface normal, the Wullf construction determines the shape of the crystal particle that minimizes the total surface energy.

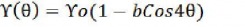

The Wullf function is given by:

As the part of my project I have further extrapolated the above equation and made Gamma a function of temperature and varied the coefficient of Theta from 2 to 10 and also replaced Cosine function with Sine function and studied the effect of changes of anisotropy on the surface evolution which have lead to some very interesting observations.

Go ahead, click next pages to find out!!